The company’s strategic elements are

A deep knowledge of the production processes of different industrial sectors that need to cut polyurethane foam permits to give to the costumer not only the suitable machine but also a good analysis and consulting on possible production scenarios.

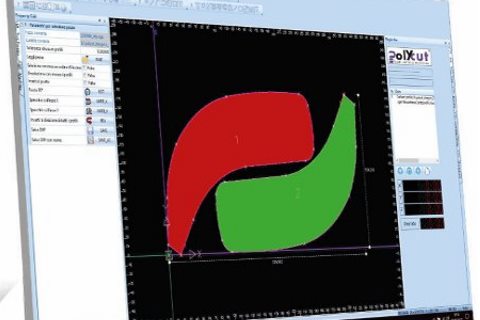

2. A deep CAD-CAM software development knowledge also with multi axis management.

Development of a photographic system of acquisition shapes that is well incorporated both with the CAD-CAM and the cutting machine.

Low costs on retrofit machines and plants in order to extend the duration of obsolete machines. The retrofit is to be understood both at a hardware and software level